Elevators are the lifeblood of modern buildings, seamlessly transporting people and goods between floors. While the technology behind them is intricate, one crucial component often goes unnoticed: the guide rails. These unassuming structures play a vital role in ensuring the smooth, safe, and efficient operation of elevators.

At TTI Lift, a leading elevator company with extensive experience, we understand the importance of quality guide rails. In this comprehensive guide, we delve into the various types of elevator guide rails, their unique characteristics, and how to choose the right ones for your specific needs.

Understanding Guide Rails: Function and Significance

Elevator guide rails act as the tracks upon which the elevator car travels. They provide vertical guidance, support, and stability to the car, ensuring its precise movement and preventing lateral swaying. They also play a crucial role in aligning the car with the landing doors and ensuring smooth door opening and closing.

Exploring the elevator guide rail types

The choice of guide rails depends on various factors, including the elevator type, building structure, and weight capacity. Here’s a breakdown of the most common types:

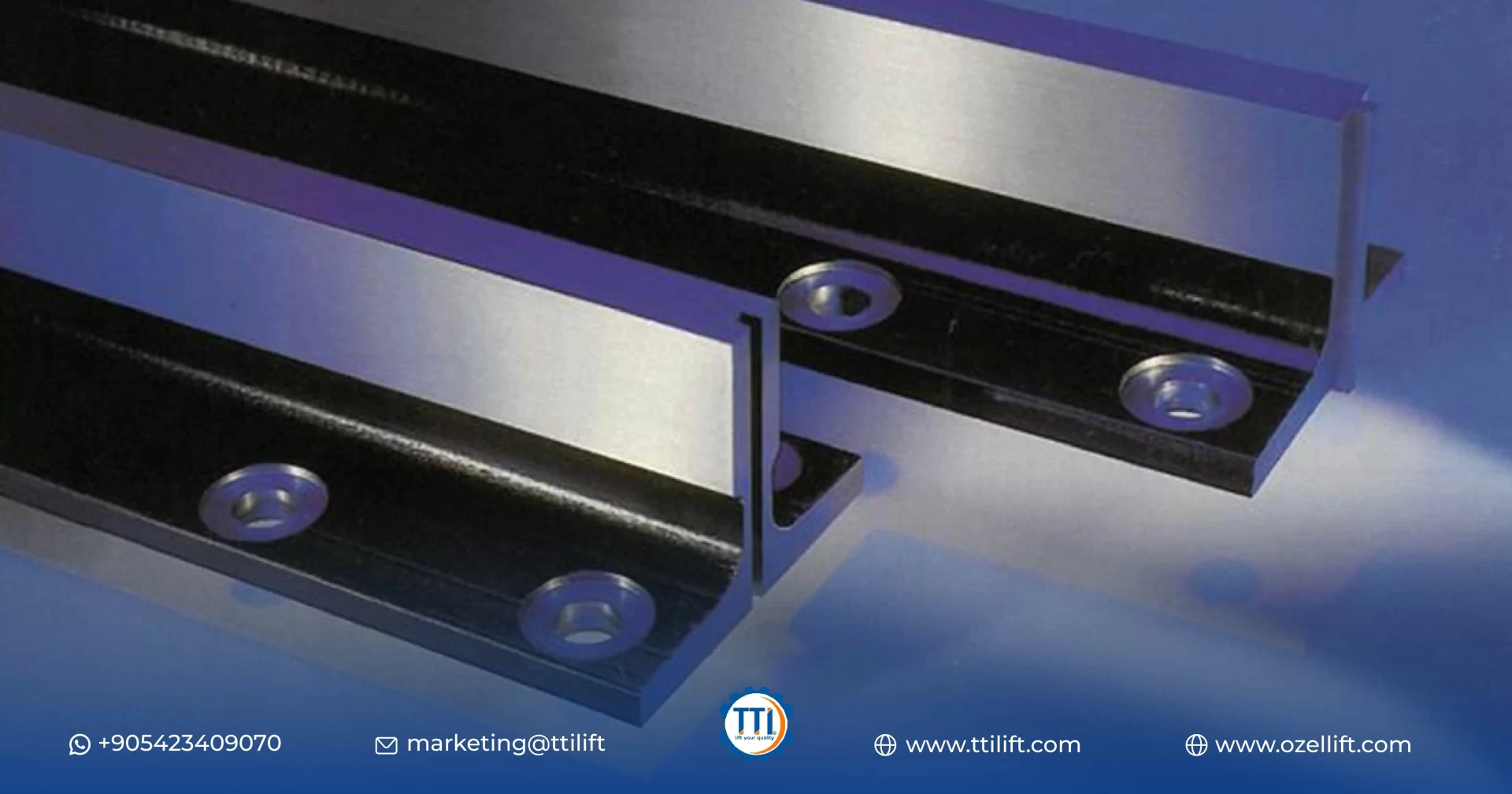

- T-Shaped Rails: These are the most commonly used type, featuring a T-shaped profile. One side of the “T” rests against the wall, while the car rollers engage with the vertical flange. Suitable for various elevator types, they offer good stability and ease of installation.

- Flat Rails: As the name suggests, these rails have a flat profile and are mounted directly onto the wall using brackets. Primarily used for low-rise elevators or applications where space is limited, they offer a clean aesthetic but require precise installation and alignment.

- Channel Rails: These U-shaped rails are enclosed on three sides, providing enhanced rigidity and better lateral stability compared to T-shaped rails. They are commonly used for heavy-duty elevators or elevators with high speeds.

- Gibbed Rails: These specialized rails feature a dovetail groove on one side, where the car’s rollers or gibs engage. This design provides exceptional stability and precision but is generally more complex and expensive than other options.

Know more about

what is an elevator?

elevator guide rail types – Additional Considerations

- Material: Guide rails are typically made of high-strength steel for durability and resistance to wear and tear. In some cases, stainless steel might be used for improved corrosion resistance or aesthetic reasons.

- Surface Finish: The surface of guide rails can be painted, galvanized, or coated with different materials to enhance their longevity and appearance.

Choosing the Right Guide Rails for Your Elevator:

Selecting the appropriate guide rails for your elevator project requires careful consideration of several factors:

- Elevator type: Passenger elevators, freight elevators, and machine room-less (MRL) elevators often have different guide rail requirements.

- Building structure: The building’s construction material and available space can influence the choice of rails (e.g., flat rails for limited space).

- Weight capacity: The elevator’s weight capacity needs to be supported by the chosen guide rails’ strength and design.

- Speed and performance: High-speed elevators may require specific types of rails for optimal stability and precision.

- Budgetary considerations: Different types and materials of guide rails vary in cost.

Know more about

Elevator door types

Lift Speed Governors

Types of elevator guide rails – Ensuring Quality and Safety:

The quality and proper installation of guide rails are crucial for elevator safety and performance. Here are some key points to remember:

- Material sourcing: Use high-quality, certified materials from reputable suppliers.

- Manufacturing: Ensure the rails are manufactured according to strict quality standards and industry specifications.

- Installation: The installation should be carried out by qualified and experienced professionals following precise guidelines.

- Regular maintenance: Conduct routine inspections and maintenance of the guide rails to ensure their integrity and prevent potential issues.

TTI Lift’s Expertise

With our extensive experience and in-depth knowledge of elevator systems, TTI Lift (TTI Group) can help you choose the most suitable type of guide rails for your needs. Our team of qualified engineers and experienced technicians will provide expert advice and guidance throughout the selection process, ensuring you get the optimal solution for your project.

Guide rails, although often unseen, are an essential component of any elevator system. Understanding the different types, their characteristics, and choosing the right ones for your specific requirements is crucial for ensuring the safety, reliability, and smooth operation of your elevator.

TTI Lift: Your trusted partner for expert guidance and comprehensive elevator solutions.

What are the different types of elevator guide rails?

T-shaped, flat, channel, and gibbed rails, each with unique strengths.

How do I choose the right guide rails for my elevator?

Consider elevator type, building structure, weight capacity, speed, and budget.

What’s the most important factor in guide rail selection?

High-quality materials and proper installation for optimal safety and performance.